K&K K&KURT MAKiNA SANAYi VE TiCARET LTD. STi. AEGEAN FREE ZONE Chocolate - Confectionery Machinery - Plants & Engineering |

LABORATORY TEMPERING MACHINE

| The

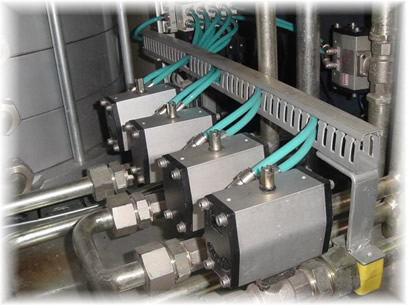

K&KURT LABORATORY TEMPERING MACHINE K&Kurt laboratory chocolate tempering machine has six plates and a highly developed three zone pre crystallizing system.

The built in gear drives the main shaft with its turbo scrapers, which turbulently mix and scrape off the individual water jacketed zones.

Two different models: one with internal water cooler, the other model uses external cold water.

Each zone has a separate

water pump that circulates the water at very high speed and thus

ensures a uniform exact water temperature in each tempering zone.

|

|

Even if the water inlet is off, the existing water will circulate and the tempering efficiency will be high.

By means of a chocolate pump with variable speed control the chocolate mass is transported through the tempering unit.

The machine is fitted with safety devices.

Robust, less disturbance and low noise.

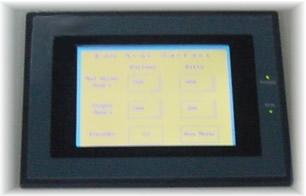

LABORATORY TEMPERING MACHINE has PLC touch screen. Easy to operate. Preset programs. |

|

|

|

|

|

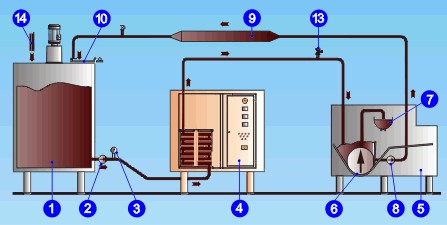

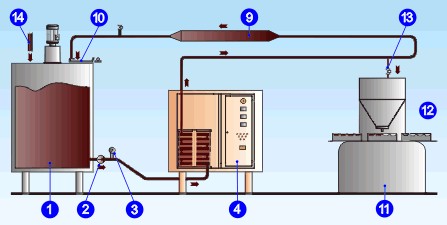

TEMPERING PROCESS DIAGRAM

|

Improved contraction for easier demoulding and less mould cleaning. Homogenous distribution of the stable seed crystals. Maximum heat transfer by means of turbulent cooling water flow. Increased shelf life and exceptional gloss due to the presence of high percentage of stable Beta V crystals. Improved heat resistance of the chocolate. Quickest solidification during the cooling process. Perfect scraping and turbulent mixing. Accurate temperature control. |

|

EXAMPLE INSTALLATION OF K&KURT CHOCOLATE TEMPERING MACHINES

| Legend 1 - Holding tank 2 - Chocolat feed pump 3 - Chocolate temperature indicator 4 - K&KURT temper machine(KTM) 5 - Coating machine (Enrober) 6 - Circulation pump 7 - Curtain trough 8 - Return pump 9 - Detempering heat exchanger 10 - Vibratory sieve 11 - Moulding machine (Depositor) 12 - Dual depositing head 13 - Automatic feed valve 14 - Supply of chocolate

|

Enrobing Plant

|

|

Moulding Plant

|

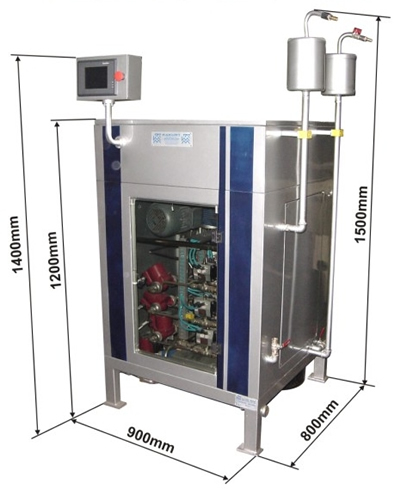

Technical data

| Model | KKT30LT |

|

| Dimensions

|

Length |

800mm |

Width |

900mm |

|

Height |

1500mm |

|

| Main motor power | 1.5

KW , 380 V |

|

| Weight |

350

kg |

|

| Capacity |

30

Kg/h |

|