K&K K&KURT MAKiNA SANAYi VE TiCARET LTD. STi. AEGEAN FREE ZONE Chocolate - Confectionery Machinery - Plants & Engineering |

|

KK5R200L 5 Roll Refiner Capacity : app 50 Kg/h (20 microns) depending on recipe Frame Rolls Drive Transmission Hydraulic system Roll cooling Scraper Control cabinet Inspection doors on both sides of the machine Stainless steel feeding trough (hopper) Stainless steel discharge chute with window All parts that contact with material is to be made of stainless steel, except the roll surface |

Feeding section

Easily moved out for cleaning rolls

The 5 roll refiner has a soft start system.

The machine can start and stop again when the rolls are under pressure.

Processing section

Five rolls

Roll Diameter: 200 mm

working width: 200 mm

Double layered cast iron

The rolls are made of special centrifugally cast iron

Dynamic balance is 750 rpm

Rolls mounted in roller bearing with grease lubrication, central greasing.

Grease lubrication pipes are central localized for easy operation.

Special helical gear wheels in enclosed boxes with forced oil lubrication for transmission.

|

Cooling system Water automatic heat sensitiv.e Solenoid valves in the cooling water cycle to allow the automatic on and off. In case of pressure drop or no water, the rolls are released from pressure and the system stops automatically. The cooling water system controlled digitally by solenoid valve system. Digital thermo controllers for the rolls controls the water very accurate. Cooling water flows over the water lance in to the roll. Water lance is equipped with thermometer and pressure gauge. Thermo sensor PT100

|

| Driving section The helical gear wheels are in the left side of the frame. It is driven with high performance V belts directly on the fifth roll, whereby the V belt pulley is installed in the machine. The roll cooling is located on a block in the right hand side of the frame. Gears are force lubricated with oil pump.

|

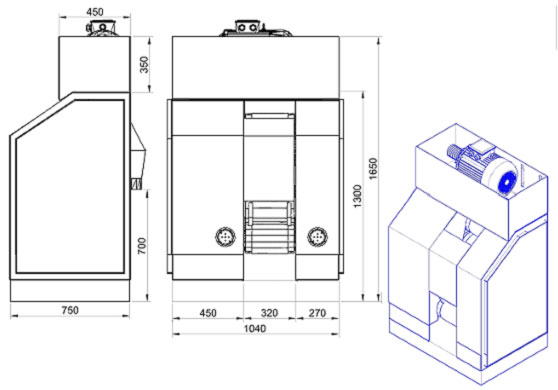

Electric control section The control unit is in an external control cabinet. Overall Specification General Dimensions: Measurements given in this offer are approximate. K&K reserves the right to change the measurements without notice. Please confirm the actual measurements after signing the purchasing contract (fig.2.39).

Measurements of Installation and Dismantling Area A (width) 570 mm B (length) 1040 mm C (Height) 1650 mm

Capacity Refining capacity of KK5R200L LABORATORY 5 ROLL REFINER depends on the following factors: - Thickness of powdered sugar and cacao - Ingredients of the cacao liquor (fat content) - Thickness of the desired refined product - Temperatures of the rollers - Previous processing (mixing etc.) of the product before fed into Product Thickness: A micrometer (µm) gauge is used to measure the thickness of the refined product. The desired thickness can be set between 12 and 40 µm. usually, the desired thickness is set to 18µ ± 4µ (check capacity diagram – fig.2.40).

Fig.2.40: Capacity Diagram On this diagram the input product thickness value has been accepted as 100 micron. Utility consumption The cooling water system The cooling surfaces of the instruments and the machine itself should be cooled by the clean and softened water. The standard cooling water should have a 2 bar pressure and maximum 8 French hardness. The pressure reducer which has been installed on the machine should be fixed to 2 Bar. Water inlet : Ø50 mm Water exit : Ø70 mm Pressure : Min. 1,5 Bar/ Max. 8 Bar Consumption : 300- 900 lt. (Min.12ºC - Max. 20ºC) Water Hardness : 8 French Hardness Electrical data: Technical Information: Environment temperature : 24 - 36 ºC Main motor protection type : Ip 54 Power of the main motor : 11 (kW) (380 V, 50 Hz) Refining capacity : (see capacity diagram) Electronics Control: Siemens PLC Hydraulic system The hydraulic pressure adjusted by giving the parameters to the PLC system. The hydraulic system is PLC driven. |