K&K K&KURT MAKiNA SANAYi VE TiCARET LTD. STi. AEGEAN FREE ZONE Chocolate - Confectionery Machinery - Plants & Engineering |

|

KK2R200 2 Roll Pre-Refiner Capacity : app 50 Kg/h (90-225 microns) depending on the recipe The KK2R200 consists of: -Frame -Rolls -Drive -Transmission -Hydraulic system -Roll cooling -Scraper -Control cabinet -Inspection doors on both sides of the machine All parts that contact with material is made of stainless steel, except the roll surface |

Feeding section

Easily moved out for cleaning rolls

Processing section

Two rolls

Roll specifications:

Roll Diameter: 200 mm

working width: 220mm

The rolls made of special centrifugally, double layered cast iron.

Rolls mounted in roller bearing with grease lubrication.

Grease lubrication pipes are central localized for easy operation, central greasing

Special helical gear wheels in enclosed boxes with forced oil lubrication for transmission.

Driving section

The helical gear wheels are in the right side of the frame.

It is driven with high performance V belts directly on the second roll, whereby the V belt pulley is installed in the machine.

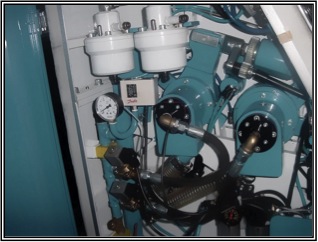

The hydraulic units and the roll cooling are located on a block in the left side of the frame.

Gears are force lubricated with oil pump

Overall Specification

W : 650 mm

h: 900 mm

l: 900 mm

Working Specification

Ambient temp: 10-40 ℃

Power motor: 3 KW

Electrical data:

Voltage: 380-440V.

Frequency: 50 Hz.

Control voltage: AC 220 V,

Electronics Control:

Siemens PLC

Hydraulic system:

The hydraulic pressure adjusted by giving the parameters to system.

Discharge section:

Scraper knife scrapes automatically without damage on the rolls.

The width of the knife is 30mm

Scraper material : special spring steel

The K&K TWO ROLL REFINER for chocolate is designed with the latest technology. Two roll refiner can be used as pre-finer before five roll refiner or stand alone refiner with multiple refining process. The crushing of chocolate ingredients between the two grinding rolls makes possible to use crystal sugar instead of powder sugar. In this way it is possible to eliminate the humidity in chocolate. Prerefiner reduces the prepared mix from 600-1000µ to 80-130µ grain thickness. It forms very well tissue with raw material’s molecules and oils. This operation improves the adhesive capability to the refiner cylinders. It lowers conche period. Prerefiner thins products with compact hydrostatic pressure system. Capacity is 10-60 kg/h.

|

|